Type:

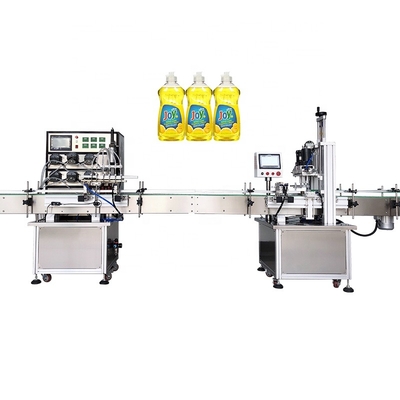

Filling Machine

Applicable Industries:

Hand Sanitizer Filling

Showroom Location:

Brazil, Kenya, Argentina

Application:

Commodity, Chemical

Packaging Type:

Bottles

Packaging Material:

Plastic, Glass

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V/50Hz, 220V/50Hz

Dimension(L*W*H):

1900*1000*1500mm

Weight:

200 KG

Warranty:

1 Year

Key Selling Points:

Easy To Operate

Machinery Capacity:

2000bph

Filling Material:

Hand Sanitizer Without Gel

Filling Accuracy:

0.01

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Pump, PLC

Product Name:

Liquid Semi Automatic Weighing Liquid Bag Dishwashing Filling Machine

Filling Accuracy:

≤±1%

Filling Speed:

20-60b/min

Filling Range:

5-200ml((others Filling Range Can Be Customized)

Air Source/consumption:

0.5-0.8MPa Clean Dry Sir Source;200L/min

Suitable For Lid:

Plastic, Metal Round Cover

Sealing Height:

50-300CM

Sealing Diameter:

16-70CM

Production Speed:

20-50 Bottles/min

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!